Premier Oilskim Systems Pvt. Ltd.

Premier Oilskim Systems Pvt. Ltd.

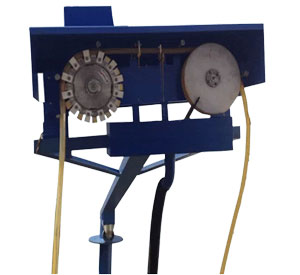

Skimmer main frame is constructed of Light Weight Aluminum Thick plates with all corrosion resistant epoxy paint coating materials. Skimmer would be supplied with rain hood cover cum safety guards. Skimmer shall be manufactured with internally lubricated for life components that do not require additional lubrication to be added to the unit. Internal drive and driven shafts shall be driven by a chain sprocket system with tensioning arrangement that is assessable easily Drive motor would be IE2/IE3 0.37KW , 71 Frame, Flange Mounting type, TEFC, 415 Volt, Three phase, Worm geared Motor. A sealed lubed for life worm gearbox reducer is coupled to the motor to operate the skimmer collector tubing drive system at the appropriate speed.

✦ DEPTH : TANK DETAILS DEPENDENT

✦ Tube Dia :18 mm

✦ Tube Speed: 30 Metres Per Minute.

✦ Pulley Speed:40 rpm.

✦ Direction Of Rotation: Anti Clockwise.

✦OIL REMOVAL CAPACITY : 100-120 LPH Depending on the site conditions and oil viscosity. Oil removal capacity of the oil skimmer may vary at the time of installation and run

✦ IE2 Efficiency CROMPTON /BHARAT BIJLEE Make Motor,0.5 HP , Three phase , AC Geared Motor of fixed 30 rpm .

✦ Foundation Anchor Bolts for Mast ,Locator ring for making MAST foundation co ordinates will be given.

✦ High Abrasion Resistant ceramic material fingers and wipers .

✦ All the fasteners ,nut bolts used would be SS 304.

✦ Swival Arm Mast MOC would be M.S. with Rustocon primer coatings and Epoxy P.U. Primer coating with 2 coats of P.U. Paint coating

✦ Main Body MOC would be Light weight engineering grade Aluminium with Epoxy painting.

✦ At the time of installation you will provide for the fabrication etc for the mounting of the skimmer mechanism at site.

✦ oil skimmer would be ready to perform continuosly for 24 hours and for 365 days a year.

✦ Suitable rain hood cover would be provided to protect the mechanism during rainy seasons if the system is to be kept in open.

✦ Imported polymer Tube is used for more tube travel life as well maximum oil removal .

✦ Tube has property of floating on top of the liquid and thus is capable of collecting maximum surface of the tank liquid.

✦We userustocon primer which is having property of forming insulation coating for rust as well converts the surface rust into protective layer and then Epoxy Polyurethane paint system which is the best possible painting scheme available today .

✦ Skimmer main frame is constructed of Light Weight Aluminium Thick plates with all corrosion resistant epoxy paint coating materials

✦ Skimmer shall be supplied with rain hood cover cum safety guards. Skimmer shall be manufactured with internally lubricated for life components that do not require additional lubrication to be added to the unit.

✦ SS316 Internal drive and driven shafts shall be driven by a chain sprocket system with tensioning arrangement that is assessable easily .

✦ Drive motor of 0.37 KW /0.5 HP, 71 Frame ,Flange Mounting type ,TEFC, 415 Volt, Three phase Motor with Worm Gear Box Coupled to motor of suitable Ratio .

✦ The skimmer parts in contact with the collector tube, including the tube scrapers,Scapper adjusting blocks, Roller Pins for tube alignment and pressure , Finger wheel and Tube Pick Up wheel shall be made of hard, abrasion resistant material that will not crack or chip.

✦ High Abrasion Resistant ceramic material fingers and wipers.

✦ Complete System Major Parts like,Shafts,etc MOC would be SS316 with buffing shine finish .

✦ All the fasteners ,nut bolts used would be SS 304.

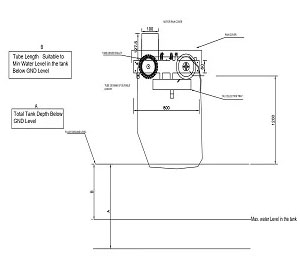

Below given are the typical Tube oil skimmer engineering specification for an industrial quality Tube Type Oil Skimmer with Dia. ¾”(18mm) Collector Tube and Foot Mount.

✦ GENERAL OBSERVATIONS:

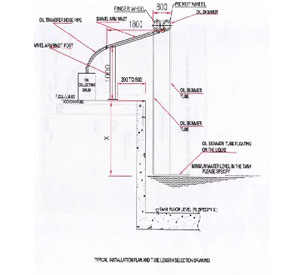

‑ Tube-type oil skimmer unit shall be used and designed for the removal of free floating oils from the surface of water in a sump. The basic advantage in using Tube type oil skimmer is that the tube floats on the water and thus more free floating oil sticks to the tube and thus it is more efficient .

‑ The skimmer shall be mounted on a pre-engineered and fabricated stand that elevates the unit such that the elevation of the oil discharge pipe is approximately 1.1 Metres above the ground level so that oil can be collected in a bigger oil collection vessel kept on the ground level. An oil collection tray is provided on the stand beneath the separator to collect the free oil from the skimmer.

‑ Oil skimmer shall operate by skimming surface oils with a 18 mm diameter floating continuous loop tube. This tube is manufactured of a material that attracts free oils and grease, while being resistant to abrasion. Oil is removed from this tube as it passes through replaceable and adjustable scrapers system made of glass filled Nylon moulded material that will not crack or chip and is highly abrasive resistant.

‑ Skimmer shall operate at a fixed speed of 35 rpm , with the following minimal design removal rate:

· Heavy oil – 50 LPH

· Medium oil – 25 LPH

· Light oil – 12 LPH

‑ Collector tube length is Tank Technical details dependent and is calculated based on the data provided by the customer.